verus compression testing|Performing a relative compression test : bulk Having a hard time diagnosing misfires due to a compression issue? In this Diagnostic Quick Tip, National Field Trainer Jason Gabrenas shows you how to find . Meuanime - Animes Online Legendado e Dublado -. Lançamentos. 8 Episódios.

{plog:ftitle_list}

WEB募集年齢は18歳から20代、30代、40代、50歳以上の女性にぴったりの、愛知(名古屋)の初心者大歓迎のアルバイト、エステ高収入です。愛知(名古屋)メンズエステ求人は 愛知(名古屋)で探すエステティシャン&セラピストのための女性求人・転職検索の一覧です。

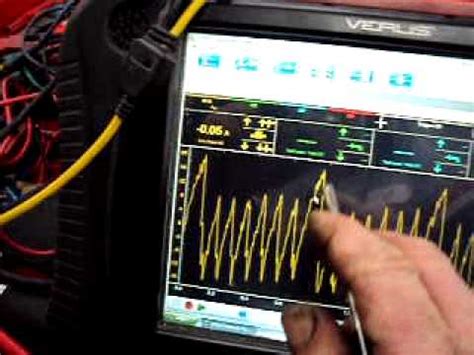

Relative compression test using the Snap-On Verus. You do not need a Snap-on scope to do these tests. Having a hard time diagnosing misfires due to a compression issue? In this Diagnostic Quick Tip, National Field Trainer Jason Gabrenas shows you how to find the .

Relative compression test using the Snap-On Verus. You do not need a Snap-on scope to do these tests. The same procedure can be followed using any Lab Scope. Engine Performance . Today I was using my snap on verus edge to do a relative compression test. My concern is the size of the waveform. I set the scope up .

Having a hard time diagnosing misfires due to a compression issue? In this Diagnostic Quick Tip, National Field Trainer Jason Gabrenas shows you how to find . Showing relative compression with a low amp probe and a Verus scope set to AC couple. Engine is a Chevy 5.3 with the no. 3 cylinder spark plug removed to sho. You may know how to do a relative compression test with a lab scope, but did you know that most late-model Fords can also perform this test as a scan tool function? In this .With a relative compression test can easily be determined whether all cylinders of an engine have the same compression. This relative compression test uses the starter motor current to determine the compression values of all cylinders.

An unconfined compression test is a simple and effective method to test the maximum load a testing a concrete sample can withstand under axial strain. The test involves applying an axial load along the sample’s longitudinal .

Compression testing determines essential parameters such as compressive yield strength, ultimate compressive strength and modulus of elasticity. Engineers then call upon this data to ensure components used in compression .

Engine CompressionAtmospheric pressure at sea level is approximately 14.7 psi.A 9:1 compression ratio cylinder is compressing the air and fuel mixture to about 132 psi at sea level (9x14.7=132.3 . This highlights the golden rule of compression testing of composites: It is not what method you choose, so much as ensuring it is used correctly that leads to accurate and reliable test results. Figure 6 – Compressive strengths of various unidirection carbon/epoxy composites as a function of slenderness ratio using different test types [7]The Compression Index C C: . Figure 2: Typical diagram of void ratio - effective stress correlation obtained by Oedometer Test. The Compression C C and Recompression C r indices are also presented. Therefore, C C is: C C = Δe / Δlog (σ') C C usually ranges from 0.1 to 10 and has no units. For normally consolidated clays the index commonly . Today I was using my snap on verus edge to do a relative compression test. My concern is the size of the waveform. I set the scope up like danner did in his video, low amp clamp 60 amp setting, scope set to volt DC, 2 volt scale, 2 second time base.

In this video I will be doing relative compression testing with 4 ch snap-on Verus. I will use low and high current clamp ,first look sensor or PPS and in . 5. Benefits of compression testing. Compression testing can provide component and product durability and reliability as well as material data for your products, helping you and ensuring that your products meet best practice standards and .Relative compression test using the Snap-On Verus. You do not need a Snap-on scope to do these tests. The same procedure can be followed using any Lab Scope. Engine Performance Diagnostics chapter 1 pages 17-22. how to use starter current to . OmniTest UTM. OmniTest Universal Testing Machines from Mecmesin. Mecmesin's top-of-the-range OmniTest universal testing machines, driven by VectorPro™ force testing software provide fully programmable control and a suite of comprehensive evaluation tools for performing a vast array of compression tests.

I take compression testing with a grain of salt. It’s really just a rough sketch of an engines condition. If you really want to know what’s happening, a leak down test is the way to go. For me a compression test is a quick way to verify an engines integrity when faced with a performance problem or no start issue. The leak down test and compression test are both diagnostic tools used to assess the condition of an engine’s internal components. The leak down test measures the percentage of pressure loss in each cylinder, indicating potential leaks or worn piston rings, while the compression test measures the maximum pressure achieved during the compression .Compression testing is one of the most fundamental types of mechanical testing, alongside tensile and flexion tests. Compression tests are used to determine a material’s behavior under applied crushing loads, and are typically conducted by applying compressive pressure to a test specimen (usually of either a cuboid or cylindrical geometry) using platens or specialized .

Micro-compression testing is a promising technique for determining mechanical properties at small length scales since it has several benefits over nanoindentation. However, as for all new techniques, experimental constraints influencing the results of such a micro-mechanical test must be considered. Here we investigate constraints imposed by .Compression testing is one of the most fundamental types of mechanical testing, alongside tensile and flexion tests. Compression tests are used to determine a material’s behavior under applied crushing loads, and are . Compression testing and assessing flexural modulus are essential for structural design and ensuring the integrity of load-bearing components. Materials with high compressive strength, such as concrete in construction, .

2.1.1 Specimens. Compression specimens are simpler than tension specimens because they do not require special arrangements for gripping. The specimens are usually simple cylinders with length, L, to diameter, d, ratio L/d, in the range 1–3, even though values of L/d up to 10 are sometimes used. If the ratio L/d is relatively large buckling may occur. . Buckling of a . Hi, Curious of the pros/cons of hot versus cold compression tests. For example, on the MB TM, the compression for diesel engines should be done with engine temperature no less than 70C. However, Ive heard that a cold compression test can be more telling in some ways than hot. Also, for.

Snap on verus edge relative compression test

Relative compression testing using a low amp probe and a Verus

There is not a lot of literature on the procedures for barrel compression testing but the G4 website does have instructions. There is a reference rod that allows the bats to be measured at the 6 inch location on the barrel. The barrel of the bat is butted up to that rod and cannot touch the sides of the compression tester frame.

Reviewing and managing potential variables is critical in compression testing, because specimens will behave differently when even the subtlest variable is introduced. To manage this variability and improve the accuracy of results, here are six tips to help you ensure data consistency test after test. 1. Document the detailsCompression testing is one of the most difficult tests which can be performed on composites, and a number of test methods and specimen designs have been proposed over the years. They have been developed primarily to avoid buckling or global instability of a composite specimen under a compressive load. In-plane compressive properties of static .

Relative compression test with a lab scope

The standard testing method for compression set is ASTM D395 (1). This test which was first approved in 1934 was originally designed for rubber, but over time has been used for other “rubber like” or elastic materials such as polyurethane elastomers. The standard conditions for compression set of rubber are 25% deflection at 70ᵒC for 22 .

Relative Compression Testing Tips

The development of suitable specimen configurations and loading methods for the compression testing of high strength composite materials has received considerable attention during the past decade, and especially during the past five years. Both experimental and analytical investigations of very specific aspects of specimen and test fixture . If you suspect that your vehicle’s engine is losing pressure in a cylinder, it can be helpful to perform a relative compression test to determine if all the . Testing an engines relative compression using an amp probe and a Verus lab scope. The engine is a Chevy 5.3 with the number 3 cylinder spark plug removed to .The consolidation properties determined from the consolidation test are used to estimate the magnitude and rate of both primary and secondary consolidation settlement of a structure or an earth fill. . Plot the log pressure versus the void ratio. Based on this plot, calculate the compression index, recompression index, and preconsolidation .

The true strain is therefore less than the nominal strain under tensile loading, but has a larger magnitude in compression. While nominal stress and strain values are sometimes plotted for uniaxial loading, it is essential to use true stress and true strain values throughout when treating more general and complex loading situations.

Relative Compression Test

WEBA jerk off instructions game with a bit of randomness. I've since learned a bit more! The game opens well (in fact I've played it several times, .

verus compression testing|Performing a relative compression test